Best Slat Cleaner for Laser & Plasma

- …

Best Slat Cleaner for Laser & Plasma

- …

SLAG REMOVAL TOOL SPECIALIST

LISEN SLAT CLEANER, Born for high-power fiber laser cutting machines!

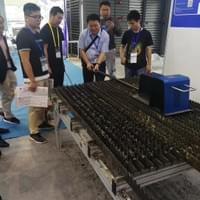

LISEN – The Leader in Slag Removal for High-Power Fiber Laser Cutting Machines

LISEN is the world’s first company dedicated solely to solving the slag removal challenges faced by high-power fiber laser cutting machines. With a clear focus on this specialized need, LISEN has emerged as the market leader, setting new standards for performance, durability, and innovation in the field.

Unlike general-purpose slat cleaners, LISEN slat cleaners are purpose-built for the demanding environment of high-power fiber laser systems (6kW and above), where slag is tougher, thicker, and more stubborn. Our cutting-edge solutions are trusted by industry giants such as Siemens, ABB, Franke Kitchen, Carlisle Brake & Friction, Marel, BYD Auto, Gree, Midea, Sany, Zoomlion, and Hitachi Elevator etc.Featured Products

Power tools for sheet metal cutting process

Laser Slat Cleaner

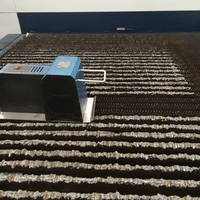

Ideal laser slag removal tool. Outstanding slats cleaning result, easy to handle and operated by one person, high efficiency, save time & energy & money

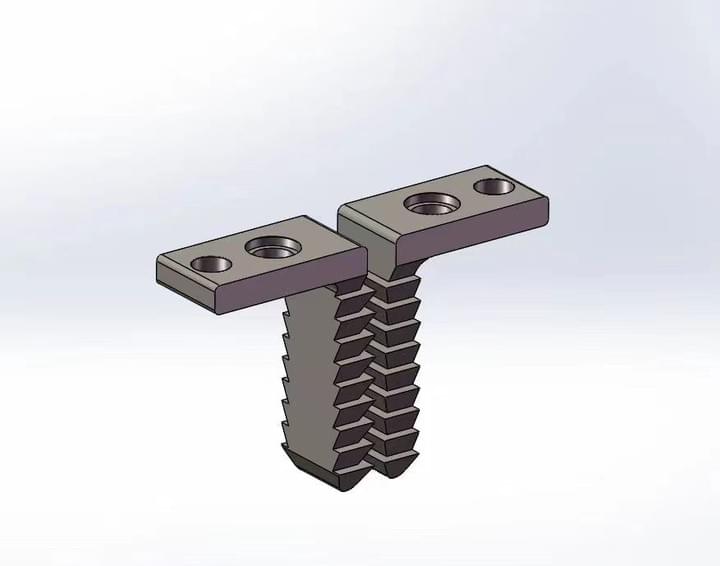

Replacement cleaning tool

The best tool steel with heat treatment, durable, powerful sharp spare parts for LSC 200 Slat cleaner

Your Ideal tool for laser slag removal

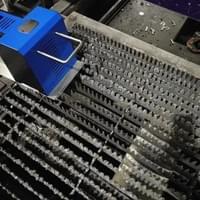

With the LISEN LSC 200 Slat cleaner, you can clean your slats quickly and effortlessly. Clean slats ensure reliable, high-quality production of laser-cut components. By cleaning the slats regularly, you can increase their service life by up to three or four times.

Amazing cleaning results

With the LISEN LSC 200, you can thoroughly remove the accumulation of slag due to our unique design and process of the slat cleaner.

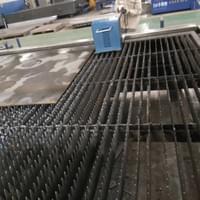

Suitable for all brands laser cutters

For use on most manufactures, such as Bystronic, Trumpf, Amada, Mitsubishi, Mazak and more, both CO2 and fiber type laser machines

Suitable for diverse metal slag

Well-suited for a variety of materials from mild steel, aluminum to stainless steel. Both available for Copper slats and Steel slats.

Simultaneous cleaning and production

Slag cleaning takes place during the cutting process on flatbed laser machines with a pallet changer.

Cost reduction up to 80%

With the LISEN LSC 200, you can clean slats multiple times before they need to be replaced.

Operated by one person

With the long machine handle and good machine handling, you can clean the slats effortlessly by yourself.

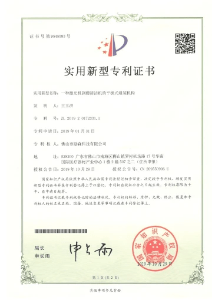

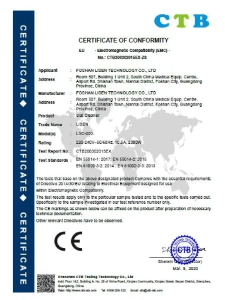

CE & PATENT CERTIFICATE

Unique Modular design,Patented product, high quality standard, CE certificated Laser slat cleaner

Patent Certificate of LISEN laser slat cleaner

unique design and patented product

We focus on laser slat cleaner and optimize our design continuously. And we have our own unique shape, internal structure, executing units and other designs. All of these have achieved successful cleaning results in practical applications. We applied patent protection and got the patent certificate accordingly. To manufacture the best laser slat cleaner in the world is our mission. We have abilities and confidence to turn it into truth. Just try our amazing laser slat cleaner, believe you will be satisfied with it.

CE certificate of LISEN laser slat cleaner

Serve all our partners in the world with best laser slat cleaner

We manufacture our LISEN laser slat cleaner with most strict standard. In the past years, our laser slat cleaner was popular among our customers in China. All of our customers are enjoying the cleaning results. LISEN laser slat cleaner makes laser slag no more one headache. We received great acceptance and when it's mature now, we would like to share our LISEN laser slat cleaner with the partners worldwide. It's time for you to try LISEN laser slat cleaner.

- Contact us and get your tools now!

Thanks for filling in the forms below

Customers' Reviews

"We switched to LISEN after struggling with heavy slag. It cleans way deeper than our old machine. Highly recommend!"

— Jake Reynolds, Production Manager"Our 6kW laser leaves brutal slag — LISEN’s high-power motor handles it without a problem. Zero regrets."

— Elena Müller, Maintenance Supervisor"Love the modular spare parts. When something wears out, it’s a 10-minute swap instead of hours of downtime."

— Carlos Perez, Operations Lead"Finally a cleaner that actually adapts toslat thickness automatically. No more tool changes between different machines!"

— Nina Foster, Fabrication Manager"The torque on this machine is insane. It powers through even wrapped slats easily."

- Ben Kowalski, Laser Machine Operator"We used Slaghog before — but LISEN goes way deeper down the slat, not just cleaning the top."

— Jean Dupont, Technical Manager"Solid, heavy-duty build. You can feel the difference from cheaper options immediately."

— Tyler Simmons, Plant Supervisor"We’re running two 10kW lasers. LISEN’s the only cleaner tough enough for the slag they produce."

— Linda Novak, Production Director"Setup was super easy. Training my team took less than an hour."

— Oscar Meyer, Workshop Leader"I love that I can push or pull the cleaner— it works in either direction depending on how the slag is sitting."

— Rachel Adams, Laser Operator"Biggest win for us was speed. LISEN clears a bed twice as fast as our previous slat cleaner."

— David Li, Operations Manager"The lubricating grease they use holds up to 300°C! We’ve had no issues with heat deformation."

— Petra Schneider, Maintenance Planner"Flexible design. One cleaner fits all our machines, from thin slats to thicker ones."

— Noah Carter, Production Technician"Before LISEN, we had to manually chip slag off. Now it’s automated, faster, safer."

— Andrés Gómez, Maintenance Team Lead"The cleaning quality is way more thorough.You can actually see clean steel after one pass."

— Liam O’Connor, Fabrication Supervisor"The motor doesn’t bog down even under heavy load. It’s built for industrial abuse."

— Hannah Mitchell, Machine Operator"Customer support from LISEN has been excellent — fast answers whenever we have questions."

— Francesco Rossi, Service Manager"Compared to others, LISEN’s machine barely needs maintenance. That’s huge for us."

— Michael Barnes, Production Supervisor"We cut a lot of aluminum — LISEN handles the different slag textures without any special settings."

— Isabel Morales, Senior Operator"Saves us about 3–4 hours of downtime per week. That's real money."

— Thomas Nguyen, Fabrication Lead"No need to buy different cleaning heads for different slat sizes. LISEN handles them all automatically."

— Emily Harris, Operations Coordinator"Handles even curved, wrapped, or misaligned slats better than anything else we tested."

— Arthur Lefevre, Production Engineer"The machine doesn’t jam or stall like our old slat cleaner used to."

— Mark Johnson, Fabrication Supervisor"We’re seeing longer slat life now because the cleaning is gentler but more effective."

— Tobias Baumann, Maintenance Lead"We used to dread cleaning days. Now it’s quick and painless."

— Ana Torres, Production Assistant"The high-torque motor doesn’t burn out like the underpowered models from other brands."

— Ethan Brooks, Machine Shop Foreman"Maintenance is simple — grease, check, go.No endless fine-tuning."

— Isabelle Wagner, Laser Operations Lead"Really impressed that it can clean even when there’s slag wrapped around the bottom of the slat."

— Victor Silva, Maintenance Engineer"The operator doesn’t have to 'fight' the machine — LISEN moves smoothly even on tough beds."

— Jason Clark, Shop Manager"Our fabricators love it. We even had one ask if we could get a second one for the other shop!"

— Sophia Keller, Production Planner"Best investment we’ve made this year."

— Daniel Foster, CEO"Tough enough for thick steel, gentle enough for thinner stainless beds too."

— Sara Jensen, Operations Head"The cleaning action is aggressive where needed but doesn’t damage the slats."

— Lucas Costa, Workshop Supervisor"It feels built for real industrial use —not hobby-level like some others."

— Felix Meier, Plant Manager"You can feel the quality of the gearbox and drive system immediately."

— Owen Price, Senior Operator"We used to think slat replacement was just 'normal’. LISEN proved we could extend life massively."

— Samantha Lewis, Plant Engineer"Very smart ergonomic design. Operators don’t get fatigued using it."

— Julie Brown, Lead Technician"For high-power lasers, you simply need a machine like LISEN. Nothing else comes close."

— Alex Weber, Laser Line Manager"We thought 8kW cutting would be too much.LISEN eats the slag for breakfast."

— Chris Martin, Operations Director"Quick changeover between machines thanks to the flexible tool setup."

— Louise Schmidt, Senior Engineer"I’ve seen a lot of cleaners — nothing matches the stability and force of this one."

— Matthew Evans, Technical Officer"If you’re serious about reducing downtime, you need to look at LISEN."

— Camila González, Fabrication Leader"Solid ROI. Paid for itself faster than expected thanks to saved labor and fewer slat replacements."

— Richard Campbell, Production Analyst"It even worked fine on slightly warped beds that would jam other machines."

— Adrian Novak, Maintenance Tech"LISEN understands heavy slag better than anyone else. You can tell it was designed by people who get it."

— George Collins, Metal Shop Manager"Big name companies trust LISEN for a reason — quality, reliability, support."

— Lucie Petit, Workshop Leader"We recommend it to anyone running lasers above 6kW. Total game-changer."

— Mason Brooks, Workshop Foreman"The old days of chiseling slag by hand are over. Thank you, LISEN!"

— Olivia Russo, Senior Operator"It's totally different after we used LISEN Slat Cleaner instead of cleaning slag by hand. Removing tough slag and dross buildup from the cutting machine support surface quickly and easily. The tool can be operated by just one person and don't need stop laser cutter running. In addition to the quality improvement of our parts, we will also save costs by saving a lot of work hours and slat raw materials when changing them. We won't ever go back. "

- Steve Wong, Fabrication Manager